G12 Epoxy Fiberglass Laminated Mapepala

Malangizo a Zamankhwala

G12 zipangizo ndi mankhwala mankhwala magetsi cholinga alkali-free fiberglass analimbitsa laminates, womangidwa ndi mkulu TG epoxy resin.It ali mkulu mawotchi mphamvu pansi kutentha yachibadwa, akadali amphamvu mawotchi mphamvu, katundu wabwino magetsi pansi youma ndi yonyowa chilengedwe, angagwiritsidwe ntchito ponyowa chilengedwe ndi thiransifoma mafuta.

Kutsatira miyezo

TS EN 60893-3-2-2009 / TS EN 60893-3-2-2011 zida zotsekera zotchinga zamagetsi thermosetting resin mafakitale hard laminates - Gawo 3-2 la zinthu zakuthupi zamtundu wa EP30893-3-2-2011

Kugwiritsa ntchito

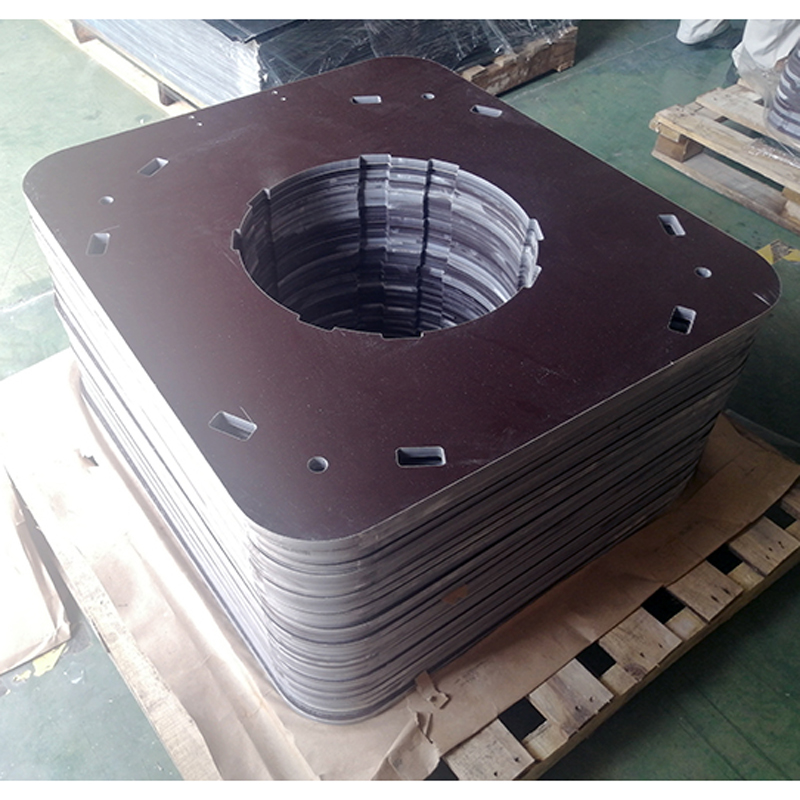

Oyenera kalasi ya 180 (H) ma traction motors, ma motors akulu ngati ma slot wedges ndi zida zamagetsi zotsika kwambiri monga zotsatira zoletsa kutentha,

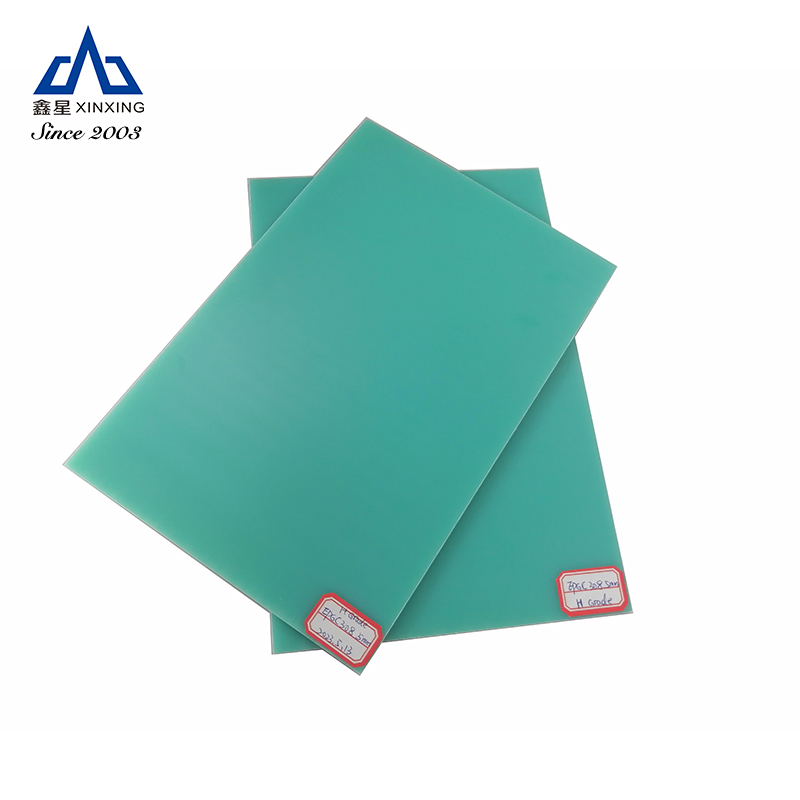

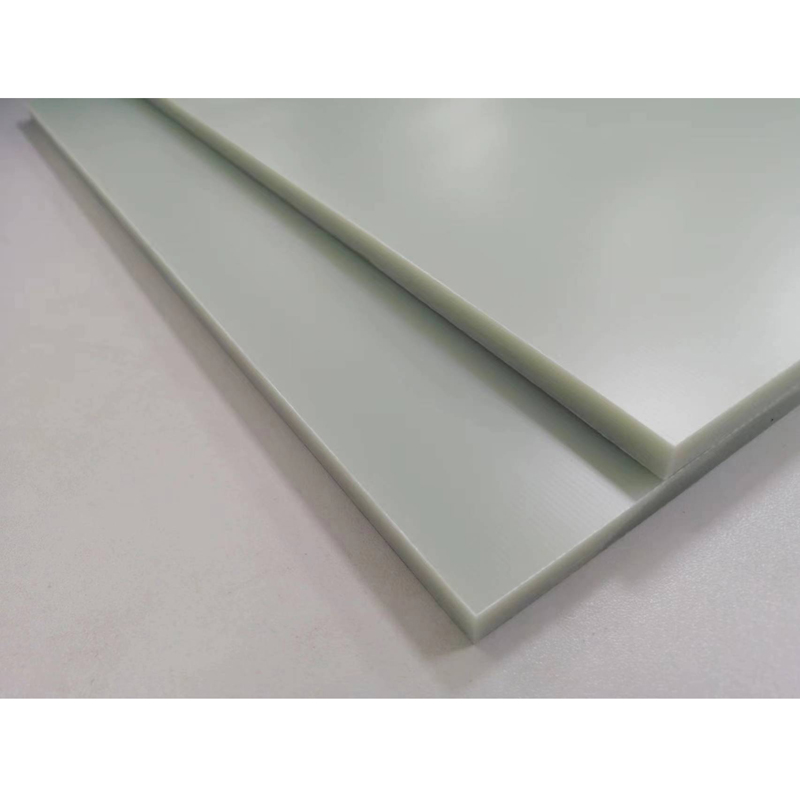

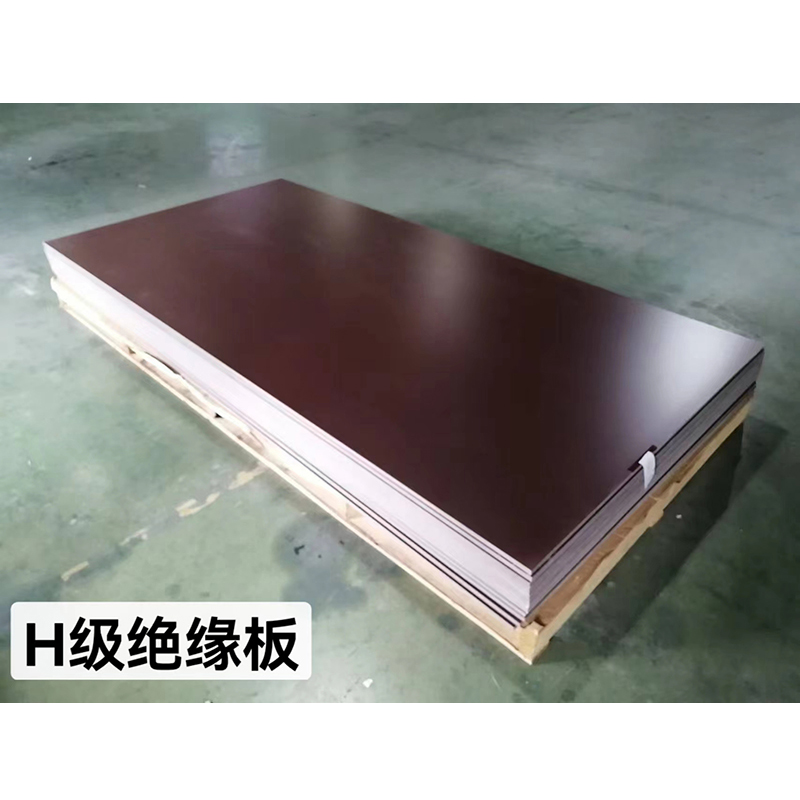

Zithunzi zamalonda

Main Technical Date(Dinani apa kuti mutsitse lipoti loyesa lachitatu)

| Kanthu | Katundu | Chigawo | Mtengo Wokhazikika | Mtengo Wodziwika | Njira Yoyesera |

| 1 | Flexural mphamvu perpendicular to laminations(MD,23℃±2℃) | MPa | ≥380 | 556 | GB/T 1303.2 |

| 2 | Flexural mphamvu perpendicular to laminations (MD, 180 ℃ ± 2 ℃) | MPa | ≥190 | 298 | |

| 3 | Flexural mphamvu perpendicular to laminations(MD,23℃±2℃) | MPa | _ | 24252 | |

| 4 | Charpy mphamvu mphamvu kufanana ndi laminations (Notched, MD) | kJ/m2 | ≥37 | 111 | |

| 5 | Mphamvu yamphamvu (MD) | MPa | ≥300 | 557 | |

| 6 | Compressive mphamvu perpendicular kuti laminations (23 ℃ ± 2 ℃) | MPa | ≥380 | 640 | |

| 7 | Compressive mphamvu perpendicular kuti laminations (180 ℃ ± 2 ℃) | MPa | ≥190 | 378 | |

| 8 | Mphamvu yamagetsi perpendicular to laminations (pa 90 ℃ ± 2 ℃ mu 25 # thiransifoma mafuta, 20s sitepe ndi sitepe mayeso, Φ25mm/Φ75mm cylindrical electrode) | kV/mm | ≥14.2 | 19.2 | |

| 9 | Kuwonongeka kwamagetsi ofanana ndi magetsi (pa 90 ℃ ± 2 ℃ mu 25 # thiransifoma mafuta, 20s sitepe ndi sitepe mayeso, Φ130mm/Φ130mm mbale electrode) | kV | ≥45 | > 100 | |

| 10 | Chilolezo Chachibale(1MHz) | _ | ≤5.5 | 5.20 | |

| 11 | Dielectric dissipation factor (1MHz) | _ | ≤0.04 | 0.0102 | |

| 12 | Kukana kutsekereza pambuyo pa kumizidwa m'madzi (MD, taper pini maelekitirodi, 25.0mm kusiyana) | Ω | ≥5.0 x1010 | 2.6x1014 | |

| 13 | Kuyamwa madzi | mg | ≤22 | 18.00 |

|

| 14 | Kuchulukana | g/cm3 | 1.7-2.0 | 1.98 | |

| 15 | Kutentha index | ℃ | _ | 180 ℃ | |

| 16 | TG | ℃ | _ | 200℃±5℃ |

FAQ

Q1: Kodi ndinu kampani yogulitsa kapena wopanga?

Ndife opanga kutsogolera magetsi insulating gulu, Takhala chinkhoswe wopanga thermoset okhwima gulu kuyambira 2003.Kukhoza kwathu ndi 6000TONS/chaka.

Q2: Zitsanzo

Zitsanzo ndi zaulere, mumangofunika kulipira mtengo wotumizira.

Q3: Kodi mumatsimikizira bwanji za kupanga kwakukulu?

Kwa maonekedwe, kukula ndi makulidwe: tidzayang'anitsitsa tisananyamule.

Pazantchito yabwino: Timagwiritsa ntchito chilinganizo chokhazikika, ndipo tikhala tikuyang'anira zitsanzo pafupipafupi, titha kupereka lipoti lowunikira zinthu tisanatumizidwe.

Q4: Nthawi yotumiza

Zimatengera kuchuluka kwa dongosolo.Kulankhula, nthawi yobereka idzakhala masiku 15-20.

Q5: Phukusi

Tidzagwiritsa ntchito pepala laukadaulo kuti tinyamule pa plywood pallet.ngati muli ndi zofunikira zapadera, tidzanyamula monga chosowa chanu.

Q6: Malipiro

TT, 30% T/T pasadakhale, ndalama musanatumizidwe. Timavomerezanso L/C.