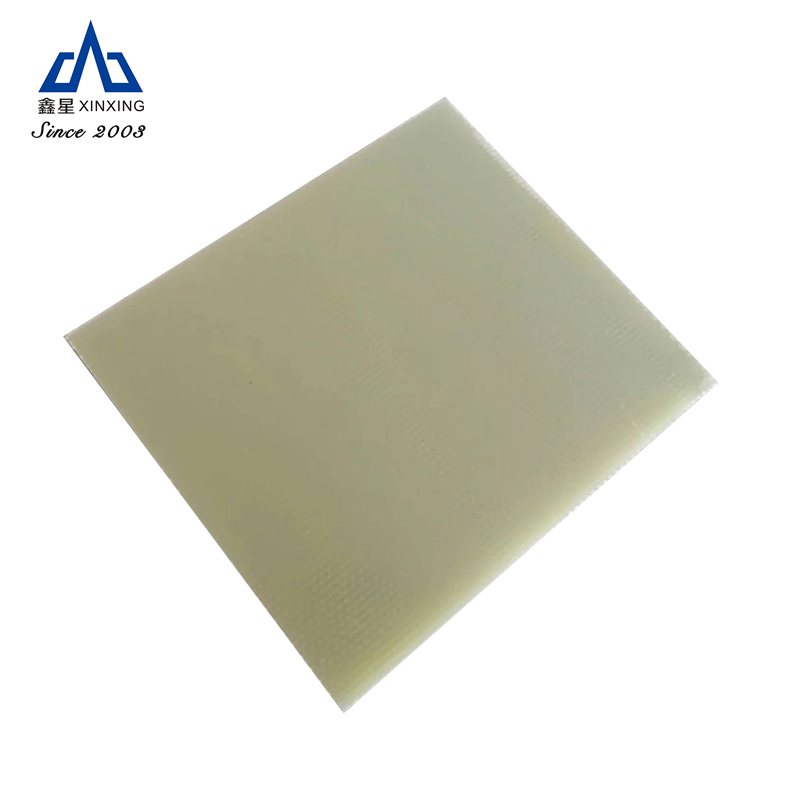

G11R Epoxy Fiberglass Laminated Sheet(EPGC205)

Malangizo a Zamankhwala

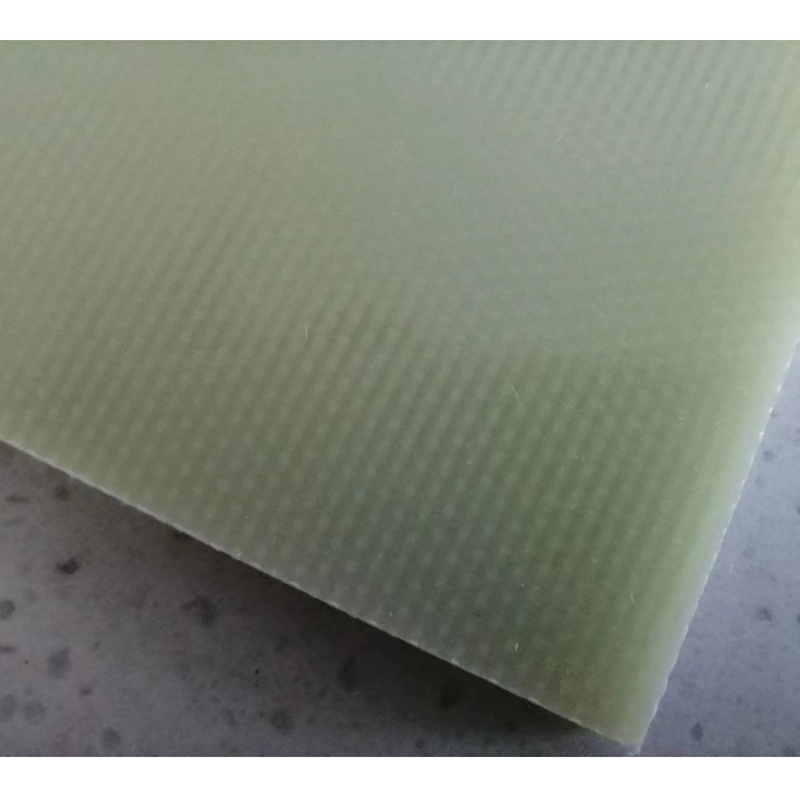

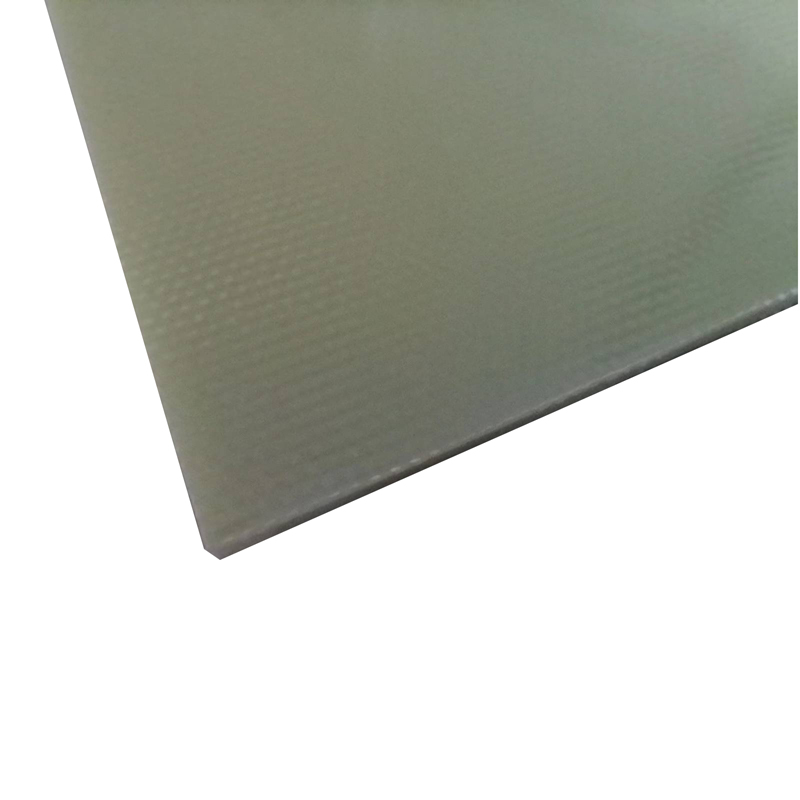

EPGC205/Roving yolimbitsa G11R ndi mapepala osalekeza opangidwa ndi fiberglass omangidwa ndi kutentha kwa epoxy resin. EPGC205/G11R ndi yofanana ndi mtundu wa EPGC203/G11R, koma yokhala ndi nsalu yozungulira. Zinthuzo zimatha kukhala ndi makina abwino kwambiri, zamagetsi ndi thupi pa kutentha kokwera kufika ku 155 ℃.

Kutsatira miyezo

TS EN 60893-3-2-2009 / TS EN 60893-3-2-2011 zida zotsekera zotchinga zamagetsi thermosetting resin mafakitale hard laminates - Gawo 4: Epoxy resin hard laminates

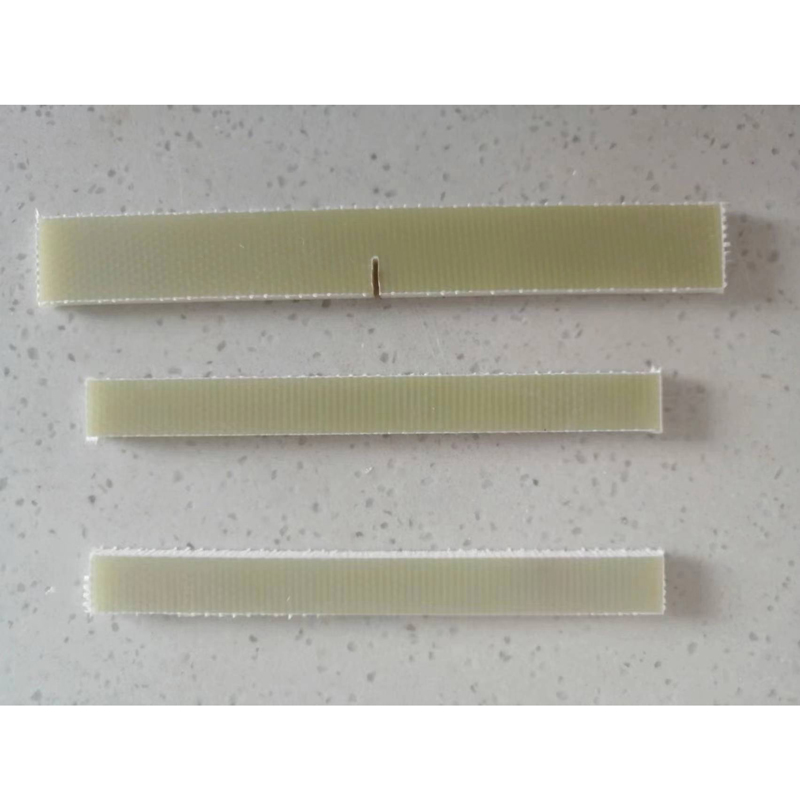

Kugwiritsa ntchito

Amagwiritsidwa ntchito kwambiri pamakina amagetsi ndi zida monga slot-wedges, fillers, mbale zovundikira, kutchinjiriza mtedza, inter mediates, mtunda, etc.

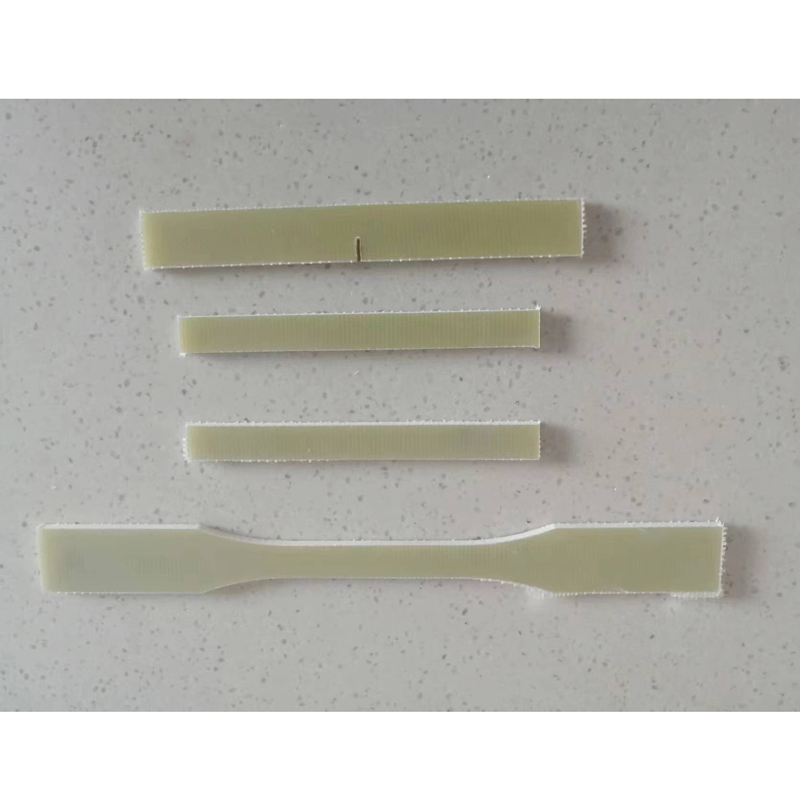

Zithunzi zamalonda

Main Technical Date(Dinani apa kuti mutsitse lipoti loyesa lachitatu)

| Kanthu | Katundu | Chigawo | Mtengo Wokhazikika | Mtengo Wodziwika | Njira Yoyesera |

| 1 | Flexural mphamvu perpendicular kwa laminations | MPa | ≥340 | 510 | GB/T 1303.2 |

| 2 | Flexural mphamvu perpendicular kwa laminations | MPa | ≥170 | 320 | |

| 3 | Kulimba kwamakokedwe | MPa | ≥300 | 530 | |

| 4 | Mphamvu ya Charpy ikufanana ndi ma laminations (Notched) | kJ/m2 | ≥70 | 170 | |

| 5 | Flexural modulus perpendicular to laminations (mu chikhalidwe chabwino) | MPa | -- | 3.2x104 | |

| 6 | Flexural modulus perpendicular to laminations (pansi pa 150 ± 5 ℃) | MPa | -- | 3.0x104 | |

| 7 | Mphamvu yamagetsi perpendicular to laminations (pa 90 ℃ ± 2 ℃ mafuta), 3mm mu makulidwe | kV/mm | ≥9 | 20 | |

| 8 | Kuwonongeka voteji kufanana laminations (pa 90 ℃ ± 2 ℃ mafuta) | kV | ≥45 | ≥50 | |

| 9 | Insulation resistance (pambuyo pa kumizidwa m'madzi kwa maola 24) | MΩ | ≥1.0×104 | 3.8 × 105 | |

| 10 | Mayamwidwe amadzi, 3mm mu makulidwe | mg | ≤22 | 17 | |

| 11 | Comparative Tracking Index(CTI) | _ | _ | Chithunzi cha CTI600 | |

| 12 | Kuchulukana | g/cm3 | 1.80 ~ 2.0 | 1.99 | |

| 13 | Kutentha index | ℃ | _ | 155 ℃ | |

| 14 | Kutentha | Kalasi | HB | HB |

FAQ

Q1: Kodi ndinu kampani yogulitsa kapena wopanga?

Ndife opanga kutsogolera magetsi insulating gulu, Takhala chinkhoswe wopanga thermoset okhwima gulu kuyambira 2003.Kukhoza kwathu ndi 6000TONS/chaka.

Q2: Zitsanzo

Zitsanzo ndi zaulere, mumangofunika kulipira mtengo wotumizira.

Q3: Kodi mumatsimikizira bwanji za kupanga kwakukulu?

Kwa maonekedwe, kukula ndi makulidwe: tidzayang'anitsitsa tisananyamule.

Pazantchito yabwino: Timagwiritsa ntchito chilinganizo chokhazikika, ndipo tikhala tikuyang'anira zitsanzo pafupipafupi, titha kupereka lipoti lowunikira zinthu tisanatumizidwe.

Q4: Nthawi yotumiza

Zimatengera kuchuluka kwa dongosolo.Kulankhula, nthawi yobereka idzakhala masiku 15-20.

Q5: Phukusi

Tidzagwiritsa ntchito pepala laukadaulo kuti tinyamule pa plywood pallet.ngati muli ndi zofunikira zapadera, tidzanyamula monga chosowa chanu.

Q6: Malipiro

TT, 30% T/T pasadakhale, ndalama musanatumizidwe. Timavomerezanso L/C.