3248 Epoxy Glassfiber Laminated Mapepala

Mafotokozedwe Akatundu

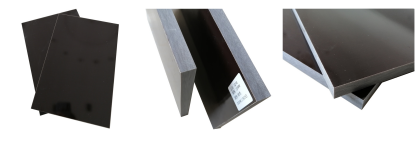

Chogulitsachi ndi chopangidwa ndi laminated chomwe chinapangidwa ndi mankhwala opangira magetsi opangira magalasi opanda alkali ngati chinthu chothandizira, pokanikiza ndi epoxy resin monga binder.Ili ndi mphamvu zamakina apamwamba kwambiri kutentha, ndi kukhazikika kwa magetsi pansi pa humidity.Thermostability ndi kalasi F, yoyenera mitundu yonse ya galimoto, zipangizo zamagetsi, zamagetsi ndi zina.

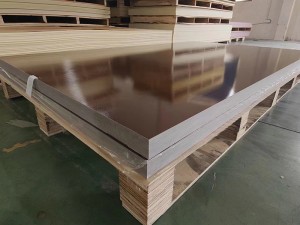

Mawonekedwe

1.Kukhazikika kwamagetsi kwabwino pansi pa chinyezi chambiri;

2.High makina mphamvu pansi mkulu

kutentha, mphamvu zamakina

kusungirako ≥50% pansi pa 155 ℃;

3.Kukana chinyezi;

4.Kukana kutentha;

5.Kukana kutentha: Gulu F

Kutsatira Miyezo

Mogwirizana ndi GB/T 1303.4-2009 magetsi thermosetting resin mafakitale zolimba laminates - Gawo 4: epoxy utomoni zolimba laminates.

Mawonekedwe: pamwamba payenera kukhala lathyathyathya, opanda thovu, maenje ndi makwinya, koma zolakwika zina zomwe sizimakhudza ntchito zimaloledwa, monga: zokopa, indentation, madontho ndi mawanga ochepa.

Kugwiritsa ntchito

Yoyenera mitundu yonse yamagalimoto, zida zamagetsi, zamagetsi ndi zina.

Main Performance Index

| AYI. | ITEM | UNIT | INDEX VALUE | |||

| 1 | Kuchulukana | g/cm³ | 1.8-2.0 | |||

| 2 | Madzi mayamwidwe Rate | % | ≤0.5 | |||

| 3 | Oima kupinda mphamvu | Wamba | Kutalika | MPa | ≥360 | |

| Chopingasa | ≥340 | |||||

| 155±2℃ | Kutalika | ≥190 | ||||

| Chopingasa | ≥170 | |||||

| 4 | Mphamvu yamphamvu (mtundu wa charpy) | kusiyana | Kutalika | KJ/m² | ≥37 | |

| Chopingasa | ≥37 | |||||

| 5 | Parallel kumeta mphamvu | MPa | ≥30 | |||

| 6 | Kulimba kwamakokedwe | Kutalika | MPa | ≥314 | ||

| Chopingasa | ≥300 | |||||

| 7 | Oima mphamvu yamagetsi (mu mafuta a 90 ℃ ± 2 ℃) | 1 mm | KV/mm | ≥17.0 | ||

| 2 mm | ≥14.9 | |||||

| 3 mm | ≥13.8 | |||||

| 8 | Parallel kuwonongeka voteji (1 min mu mafuta 90 ℃ ± 2 ℃) | KV | ≥40 | |||

| 9 | Dielectric dissiption factor (50Hz) | - | ≤0.04 | |||

| 10 | Parallel Insulation Resistance | Wamba | Ω | ≥1.0×1012 | ||

| Pambuyo pakuwuka kwa maola 24 | ≥1.0×1010 | |||||